BentoSEAL

Pre-hydrated Bentonite Tanking

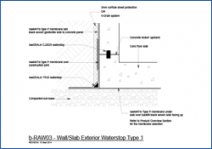

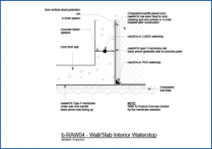

BentoSEAL is geosynthetic clay liner (GCL) consisting of a thin layer of low permeable sodium bentonite and two layers of geotextile: PP woven fabric and PP non-woven fabric. The Geosynthetic Clay Liner, or GCL, is a new environmentally friendly composite waterproof and impermeable material. It fills bentonite particles between the woven geotextile and non-woven geotextile, and composes the non-woven fabric fibres on the upper layer through bentonite particles, through special techniques and equipment and on the woven fabric on the lower layer by means of acupuncture. At the same time, according to the needs of the project, you can also supply a version with a layer of HDPE film (high-density polyethylene film) on the bentonite sheet, to adapt to the laying of special environment, in order to achieve double waterproof, impermeable effect. BentoSEAL has been proven to provide engineering performance and durability.

Waterproof properties of BentoSEAL natural sodium bentonite blanket: Natural sodium base bentonite with high swelling (bentonite particles suction volume expandable itself after 10 ~ 30 times). After the bentonite waterproofing sheet is immersed in water, the sodium base bentonite absorbs, under a certain extrusion (from basal, temporary protective layer, backfill and waterproof sheet fibre internal tension, etc.), alternates between molecular arrangement, internal space narrows to form a dense gel structure layer, water molecules can't break through, thus giving the waterproof effect. The permeability coefficient of 5 x 10 to 11 m/s. The higher the extrusion pressure, the higher the density and the better the waterproof effect.

Classification and specification of BentoSEAL natural sodium bentonite waterproofing: The natural sodium bentonite waterproof sheet finished rolls supplied by Sealco Ltd are needle-punched (GCL-NP/N) and coated (GCL-of /N) according to their categories.

-

Basements, Garage and Underground Construction

ButtonEcoTUFF comes in up to a 3.7m wide sheet that is ideal for large area commercial projects

especially where speed and quality is of essence.

-

Water landscaping and Ponds

ButtonEcoTUFF membrane is very competitive compared to other options.

-

Subway & Tunnel Works

ButtonThe benefits of EcoTUFF TPO will add value to your architectural design.

Extra large sheets

Heat weldable seams and detailing

Polyester reinforced sheet

Eco Friendly

Light colours available

Features and advantages

Green and environmental protection

The raw materials used by BentoSEAL are all natural sodium bentonite, which is made in heaven and does not need any additives to meet relevant national standards. It does not age, corrode or deteriorate, and does not cause any harm or pollution to human body and the environment.

Simple construction

Only use bentonite powder and nails, gaskets to connect and fix; It is not affected by the weather such as temperature and construction environment, and can be directly constructed in cold and wet environment. Natural lap: sprinkle bentonite powder on the lap joint, and the bentonite waterproof blanket can lap by itself when it meets water. It is the only material in the world to start the waterproof function with water. No special inspection is required upon completion; It is easy to repair if a waterproofing defect is found. Among the existing waterproof materials, GCL has the shortest construction period and the easiest operation. It has remarkable effect on shortening time limit and saving cost.

Permanent waterproofing, excellent performance

Natural sodium bentonite has been achieved for hundreds of millions of years, waterproof performance is often more durable than buildings. Sodium bentonite forms a high-density diaphragm under water pressure. When the thickness is 3mm, the permeability is & Alpha. * 10-11/s below (α =1-9), which is equivalent to the density of clay with a thickness of 100 times 30cm, showing its self-water retention property.

Strong self-repair ability

The integration of waterproof materials and objects enables the sodium bentonite to expand 20-28 times when it meets water. Even if the concrete structure vibrates and settlement occurs, bentonite in GCL can immediately repair cracks on the concrete surface within 2mm. Perforations up to 30mm in diameter can be fully recovered within 15 days.