DekMASTER is a high quality, fully cured vinyl resin material impregnated onto a non-woven polyester fabric back. DekMASTER is an aesthetic and trafficable waterproofing membrane all-in-one and is known as the best trafficable membrane available in New Zealand. It will protect your home and provide a watertight and affordable exposed deck membrane system.

DekMASTER will prevent moisture entering into your substrate preventing damage from rot or mould. DekMASTER has an aesthetic textured finish that meets the wet non-slip requirements for trafficable decks and will give a better slip resistance than a smooth surface membrane. Supplied in a 1.8m wide sheet form and all laps and penetrations are fully heat welded, the DekMASTER gives you confidence and assurance of a fully watertight deck.

Features and advantages

Trafficable membrane

DekMASTER is an all-in-one waterproofing membrane that is trafficable.

Easy to maintain

DekMASTER can be easily maintained and cleaned with the ‘Duke’ cleaner and water.

Colour options

DekMASTER is available in 4 colour options including the new ‘Barn Board’.

Cost competitive

DekMASTER is significantly cheaper than other waterproofing membrane and deck options.

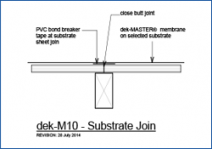

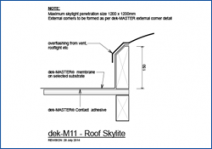

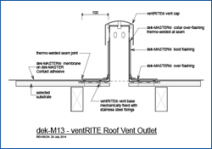

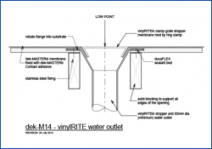

Welded seams & details

Fully welded detailing makes the DekMASTER a strong watertight membrane.

15 Year warranty

DekMASTER comes with a 15 year materials warranty.

Wide range of use

DekMASTER can be used from residential houses to high end apartments and light commercial applications.

Frequently Asked Questions

- How do I clean and maintain my DekMASTER Vinyl?

The Dek-Master® Vinyl Deck system is designed for easy maintenance. Please use the Duke cleaner as per instructions available from Sealco.

- Can I install the DekMASTER System over Fibreglass?

Yes, sand the fibreglass with 50 grit sandpaper, this will rough up the fibreglass to allow for better adhesion. Fibreglass is a very rigid material and the wood sub-structure is constantly moving because of temperature and moisture content in the air so cracks in the fibreglass may develop. The fibreglass may have also lifted away from the plywood sub-surface causing a large bubble in the finished surface. The cracks and bubbles should be cut out and new fibreglass applied (patch kit) in this area and then the Dek-Master® vinyl can be installed. NOTE: Sealco does not warranty the sub-surface to which the vinyl has been applied, if the substrate is the cause of the failure, your warranty will be null & void. Sealco always recommends a new plywood sub-surface prior to installing the vinyl.

- What is my working time with the DekMASTER adhesive?

The reason the Dek-Master® vinyl system has been so successful is our adhesive. The Dek-Master® Adhesives are waterproof, easy to apply, and long-lasting. When applied at the correct working temperature, Dek-Master® Regular Water Based Adhesive & Dek-Master® Low Temperature Adhesive will allow for a drying time of one hour. Dek-Master® SnapTac Fast Dry Adhesive & Dek-Master® Pro-Series Exterior Contact Adhesive will allow for a working time of 15 minutes.

- How do you apply the DekMASTER during inclement or unpredictable weather?

Most decking installs rely on the good sunny weather of the summer months, but decking installs can also be done during the fall, winter, and early spring by following these procedures.

On one dry day with a temperature above 8C, screw down plywood, nail flashing, and cant strip and fill all joints and surface imperfections with Dekmaster Dek-Patch until flush. Apply a primer coat of Dek-Master® Low Temp Adhesive at the rate of 300 sq. ft. per 2.5 U.S. Gal pail. Dekmaster adhesive is also waterproof therefore creating a waterproof membrane layer over the plywood, not allowing the plywood to get wet. On the next dry day with a temperature above 8C, install the Dek-Master® vinyl as you would normally, the use of a fan/blower over the wet adhesive will help to drive off the solvents.

NOTE: The Dek-Master® Adhesive, when applied as a primer/sealer, can only be left exposed to the weather extremes for a maximum of 2-4 weeks.

- How do I remove the DekMASTER vinyl once it has been glued down for a number of years?

The simplest way to remove the vinyl from the sub-surface is to razor knife the vinyl every 100-150mm, making parallel lines (it is impossible to remove the vinyl as one full sheet). Pick a warm day and pull off the strips. Check the plywood sub-surface for rot, sponginess or decay. Remove affected areas and replace with new plywood. Scrape off any high spots, fill in any low spots and re-apply new Dek-Master® vinyl.

NOTE: Sealco does not warranty the sub-surface to which the vinyl has been applied. If the substrate is the cause of the failure, your warranty will be null & void. Sealco always recommends a new plywood sub-surface prior to installing the vinyl.

- Can I install the DekMASTER vinyl deck system over a previously coated or painted plywood deck surface?

The Dek-Master® Vinyl Deck system can be applied over some previously coated decks. Compatible sub-surfaces are Acrylic, Hypalon® and Neoprene® deck coatings.

Painted surfaces such as oil or latex stains, enamels and porch & floor paints are not compatible with the Dek-Master® system. The lack of bond strength of these products combined with no waterproofing characteristics, does not make for a suitable surface. Sealco recommends sanding the paint off down to bare plywood, a belt sander works best. Check for rotten or spongy plywood, replace as necessary, allow the plywood to dry for 5 to 7 days. A tarp may be required to keep the deck dry.

NOTE: From past experiences, depending on the porosity of the plywood, the consumption rate of our adhesive increases by 25%.

NOTE: Sealco does not warranty the sub-surface to which the vinyl has been applied, if the substrate is the cause of the failure, your warranty will be null & void. Sealco always recommends a new plywood sub-surface prior to installing the vinyl.

- Can I install the DekMASTER vinyl over a slotted lumber deck?

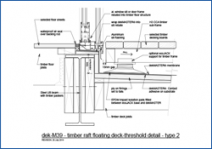

You cannot install the Dek-Master® directly over top of a slotted lumber deck. The gaps between the lumber will telegraph through. The Dek-Master® needs a solid sub-surface to be applied onto. The simplest solution is to sheet over with 17-19mm H3 CCA plywood, the plywood must be glued and screwed using a suitable construction adhesive. Slotted lumber decks are built level, a minimum slope of 1.5deg is required to adequately drain the water away and off the deck. To slope your deck, jack up 1 post at a time and cut off the required amount to achieve proper slope or build a frame over the existing timber. Make sure the new plywood is not higher than the threshold of the door (100mm minimum required), if so all slotted lumber should be removed before re-sheeting with 17-19mm H3 CCA plywood.

- At what temperature can I apply the DekMASTER vinyl?

Dekmaster manufactures 5 adhesives to compensate for a wide temperature range. Two options are available ex stock in NZ.

NOTE: Do not use Dekmaster solvent-based adhesive when working indoors, use Dekmaster Regular Water Based Adhesive. Helpful Hint: the use of a fan or blower will help to evaporate the solvent or water from the adhesive allowing for faster contact time.

RECOMMENDED WORKING TEMPERATURE FOR DEKMASTER ADHESIVE

7°C to 32°C Dek-Master® SnapTac Fast Dry Adhesive (Solvent-Based).

7°C to 32°C Dek-Master® Pro-Series Exterior Contact Adhesive (Solvent-Based).

- How do I remove accidental adhesive spills once they have dried?

Accidental spilling of the solvent based adhesive onto your finished vinyl surface is going to happen at some time, to someone. This quick and easy method of removing the adhesive is a lifesaver.

Removing Dek-Master® Solvent Based Adhesive From Vinyl Surface

Allow the adhesive spill to dry on the deck. Using a regular contact cement, lightly coat the spill. Once it is partially dried (tacky), roll it up with your thumb (balling it up).

NOTE: Do not use solvents. By the time you have cleaned up the spill, you will have also pulled the colour out of the vinyl.

Removing Dek-Master® Water Based Adhesive from Vinyl Surface

Clean adhesive immediately with water and a damp cloth.

- Can I apply the DekMASTER vinyl over previously installed vinyl?

Although it is possible, It is usually not recommend to apply the Dek-Master® vinyl over previously installed vinyl due to the sub-surface may not be sound and rot may be present in the plywood sub-surface. Only an approved installer is able to verify if an overlay option is suitable.

NOTE: Sealco does not warranty the sub-surface to which the vinyl has been applied. If the sub-surface is the cause of a failure, your warranty will be null & void. Sealco always recommends a new plywood sub-surface prior to installing the vinyl.

- How do I repair a cut, tear or large tear?

1. Contact your local approved Dekmaster applicator.

2. Clean your deck with Dekmaster “The Duke” all-purpose cleaner & degreaser following the directions on the label.

3. Using a flat head screwdriver gently pry up the vinyl on either side of the cut about 25mm. If moisture has permeated the plywood, allow to dry for 3 to 4 days.

4. Ensure the area is clean & dry then mask off on either side of the cut with masking tape to protect the top surface of the vinyl.

5. Cut a piece of Dekmaster to be 25mm larger than the tear in both width & length and with rounded corners.

6. Place patch over the tear and using the leister welder, weld the overlap area ensuring to penny roll the edges of the lap down on to the existing deck.

Most likely your vinyl patch will look different from the rest of your deck. If you would like a consistent looking deck surface Vinyl Re-Fresh may be used to bring your deck back to an aesthetically pleasing finish. Your vinyl deck surface must be leak free before applying. Vinyl Re-Fresh is tinted at the store to any pastel based colour and must be re-applied every 2 years.